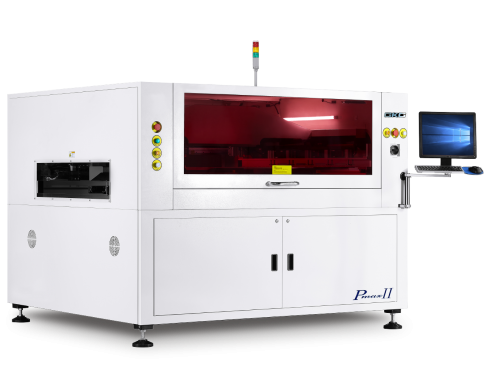

Pmax-II

High-Precision Solution for Ultra-Large PCB Printing

The Pmax-II is purpose-built for the most demanding large-format printing applications, supporting PCBs up to 1200mm × 800mm.

Its dual U-shape belt conveyor, combined with GKG’s patented clamping system, ensures stable transport and superior flatness for panels weighing up to 10 kg. This heavy-load capability delivers the strength and reliability essential for multi-layer boards widely used in automotive electronics, telecommunications, medical devices, and consumer electronics.

Every GKG printer is rigorously tested to ensure exceptional quality and reliability. With ±25 microns accuracy, the Pmax-II supports any mix and any volume, from high-mix low-volume to high-volume high-precision SMT production, delivering the flexibility and scalability that modern manufacturers demand.

| Performance | |

| Machine Alignment Capability | 2 Cmk @ ± 12.5 microns 6 sigma |

| Process Alignment Capability | 2 Cpk @ ± 25 microns 6 sigma |

| Core Cycle Time (excluding printing & cleaning time) |

< 12 secs |

| Product Changeover Time | < 5 mins |

| New Product Set-up Time | < 10 mins |

| Board Handling | |

| Max. Size (L x W) | 1200 mm x 800 mm |

| Min. Size (L x W) | 100 mm x 65 mm |

| Thickness | 0.4~10 mm |

| PCB Thickness Adjustment | Automatic |

| PCB Max. Weight | 10 kg |

| PCB Edge Clearance | 4.5 mm |

| PCB Bottom Clearance | 23 mm |

| PCB Warpage | Max. 1% diagonally |

| Clamping Method | Retractable top clamp, motor controlled side clamp |

| Support Method | Magnetic support pins, bars, blocks, vacuum suction |

| Conveyor Direction | L to R, R to L, R to R, L to L (software control) |

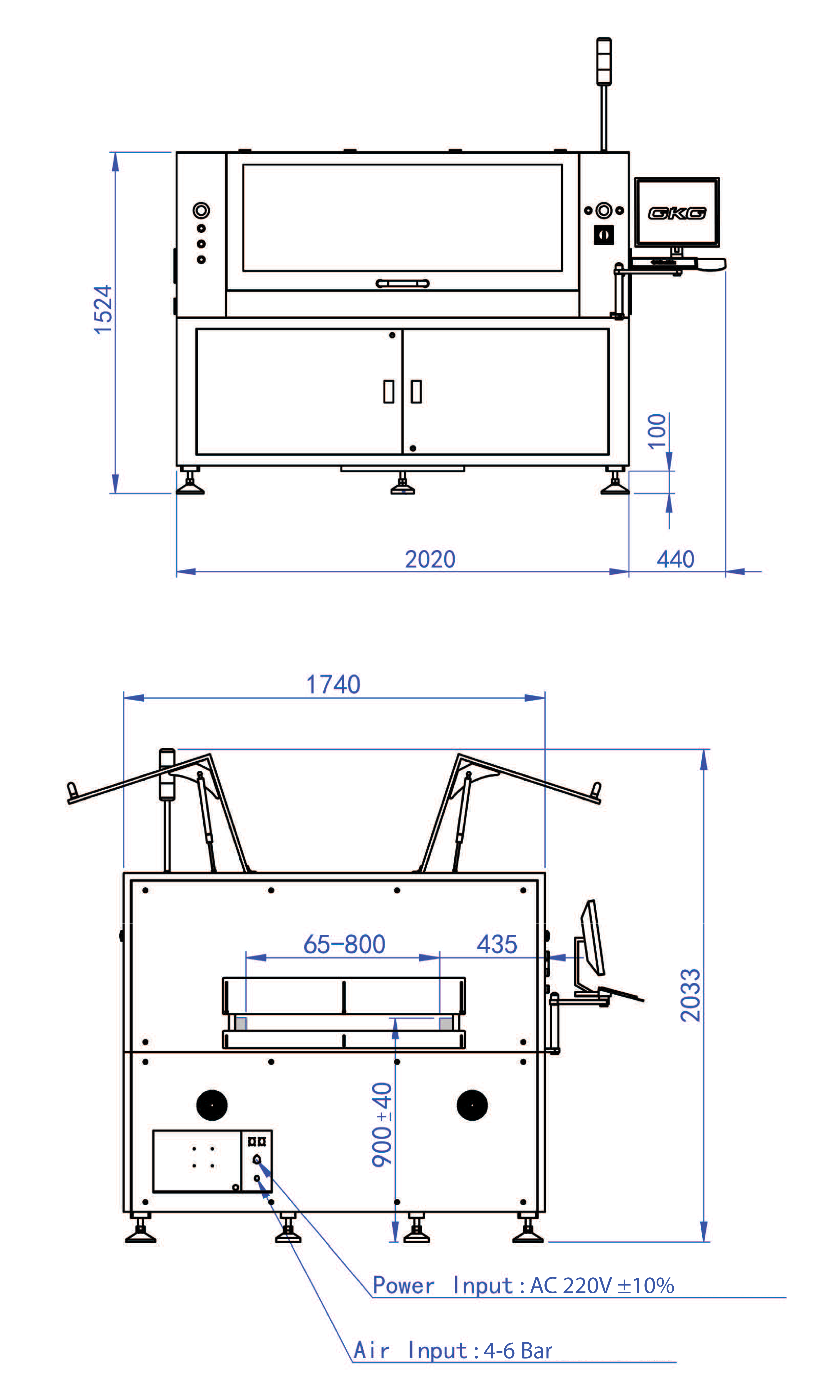

| Conveyor Height | 900 ± 40 mm |

| Conveyor Speed | Max. 1,500 mm/s |

| Conveyor Width Adjustment | Automatic |

| OPERATOR INTERFACE | |

| Hardware | LCD Monitor, Mouse & Keyboard |

| Operating System (OS) | Windows 10 |

| Control Method | Industrial PC controlled |

| I/O Interface | SMEMA Standard |

| OPTIONS |

| Auto Paste Replenishment (OPC) |

| Paste Rolling Diameter Monitoring System (OPC) |

| OPC Squeegee |

| Stencil Lock |

| Stencil Apertures Inspection System |

| SPI closed-loop System |

| Camera QR Code Scanner |

| External Barcode/QR Code Scanner for PCB Traceability |

| Handheld Barcode Scanner for stencil, solder paste, squeegee traceability |

| Temperature and Humidity Display System |

| PRINTING PARAMETERS | |

| Stencil Frame Size (L X W) | Adjustable, 737mm x 737mm to 1500mm x 1250mm |

| Print Gap (snap-off) | 0~20 mm |

| Printing Table Adjustment Range | X: ±10 mm, Y: ±10 mm, θ: ± 2° |

| Print Speed | 5~200 mm/s |

| Squeegee Pressure | 0.5~30kg (program control) |

| Squeegee Type | Std.: Metal: 720mm, 1,210mm |

| Squeegee Angle | Std. 60°, Option 45°, 50°, 55° |

| Cleaning System | Auto wet, dry, vacuum (Software select) |

| FACILITIES REQUIREMENT | |

| Power Supply | AC220V ± 10% 50/60Hz |

| Air Supply | 4 ~ 6Kgf/cm² |

| Power Consumption | 3kW |

| Dimension (excluding signal tower) (2 units back-to-back) | 2,020 mm (L) x 1,740mm (W) x 1,524mm (H) |

| Machine Weight | 1,800kg |

| OPTICAL SYSTEM | |

| Field-of-View (FOV) | 10 mm x 8 mm |

| Fiducial Types | Circle, triangle, square, diamond, cross |

| Fiducial size | 0.1~6.0 mm |

| Vision Methodology | Digital CCD camera look up & down |

| 2D inspection | Max. 500 windows to inspect missing, insufficient, bridging (std.) |