SEMICON CHINA 2024 & PRODUCTRONICA CHINA 2024

![]()

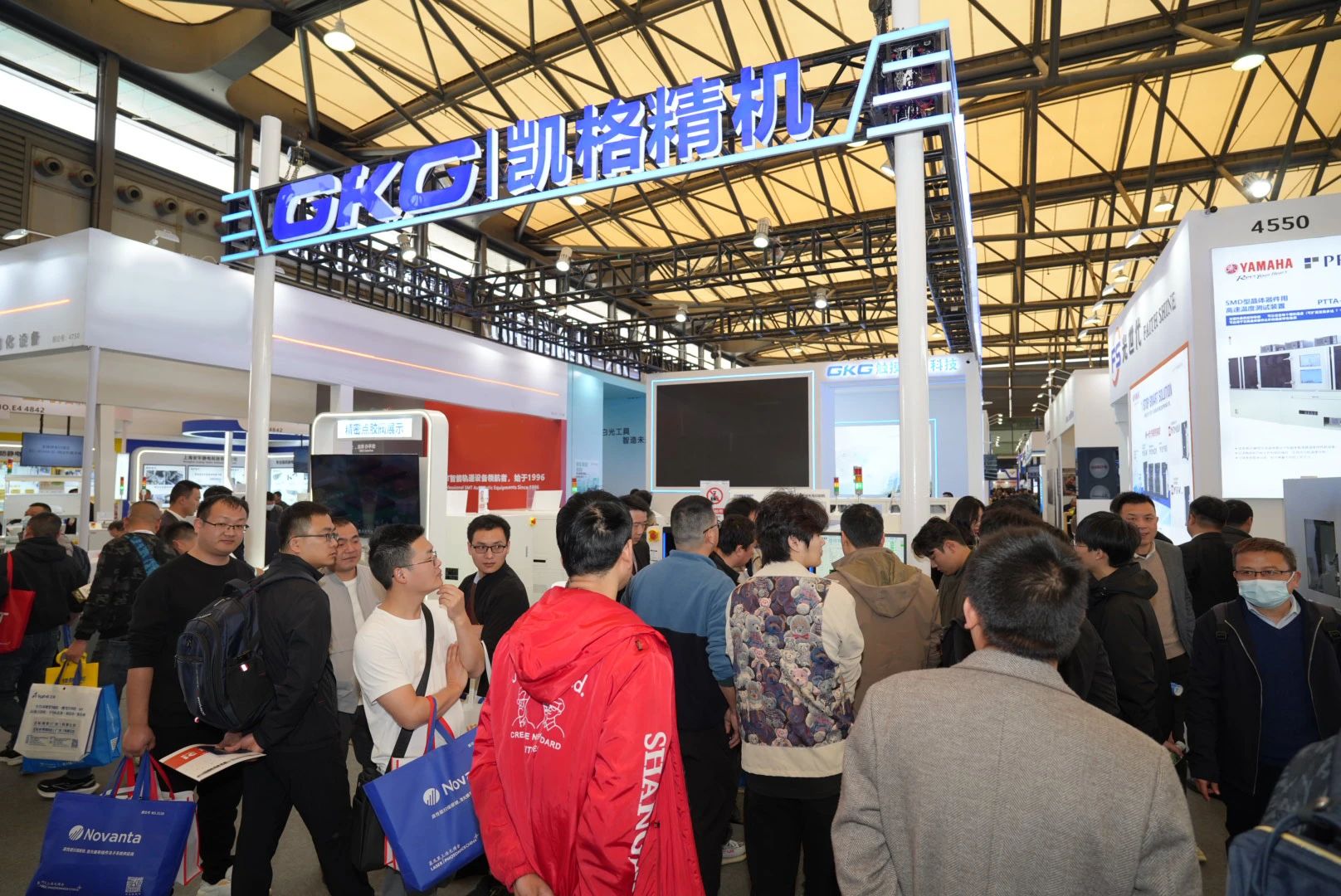

On March 20-22, 2024, SEMICON China 2024 and Productronica China 2024 were held simultaneously in Shanghai, one of the busiest cities in China. Together, we aimed to build the era of electronic manufacturing and semiconductor technology.

———— SEMICON CHINA 2024 ————

GKG unveiled its latest developed machines at the exhibition, including the fully-automatic semiconductor printer, ARES and fully automatic high-speed dispensing machine D-Semi.

In the 6 Sigma process range, the positioning accuracy can reach ±8μm with CPK≥2.0, and the printing accuracy is ±12.5μm with CPK≥2.0, with less than 5 seconds of NCP-Cycle Time. It meets the requirements of 01005, printing gaps of 30μm and above, and is compatible with solder paste, flux, silver paste, and other applications.

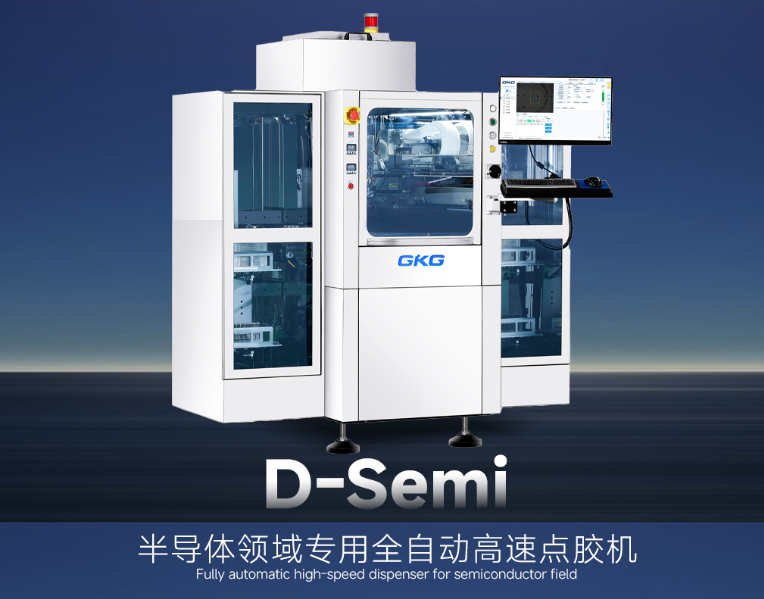

GKG also showcased the D-Semi, a specialized fully automatic high-speed dispensing machine for the semiconductor industry. With a minimum solder dot diameter of 80μm, a volume of 0.015mg per dot, and up to ±5μm positioning accuracy, it is capable of supporting various dispensing processes within the semiconductor industry.

———— PRODUCTRONICA CHINA 2024 ————

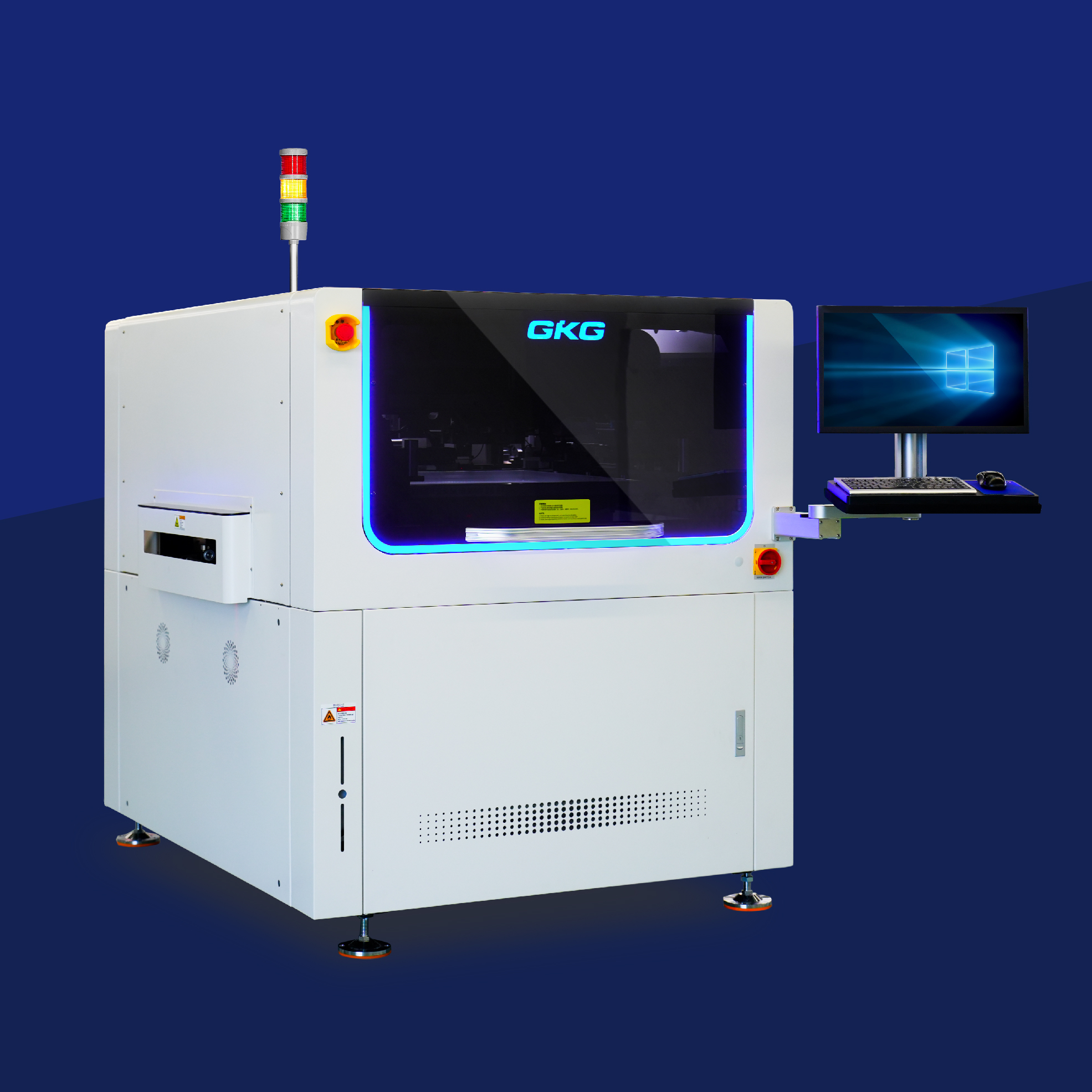

During Productronica China 2024, GKG showcased the all-new high-performance Fully-Automatic SMT Printer, G-Tera, during Productronica China 2024. Combining “High Precision, High Speed, High Intelligence” into one machine, it is applicable in the fields of 3C products, aviation, 5G, medical devices, electronic vehicles, and semiconductor packaging.

In the 6 Sigma process range, the positioning accuracy can reach ±8μm with CPK≥2.0, and the printing accuracy is ±12.5μm with CPK≥2.0. The maximum printing board size is up to 510mm x 510mm, and the minimum board size is 50mm x 50mm. Built with a single or three-stage conveyor design, it reduces cycle time to less than 5.5 seconds. The G-Tera meets the requirements of 01005, printing gaps of 30μm and above, and is compatible with solder paste, flux, silver paste, and other applications.

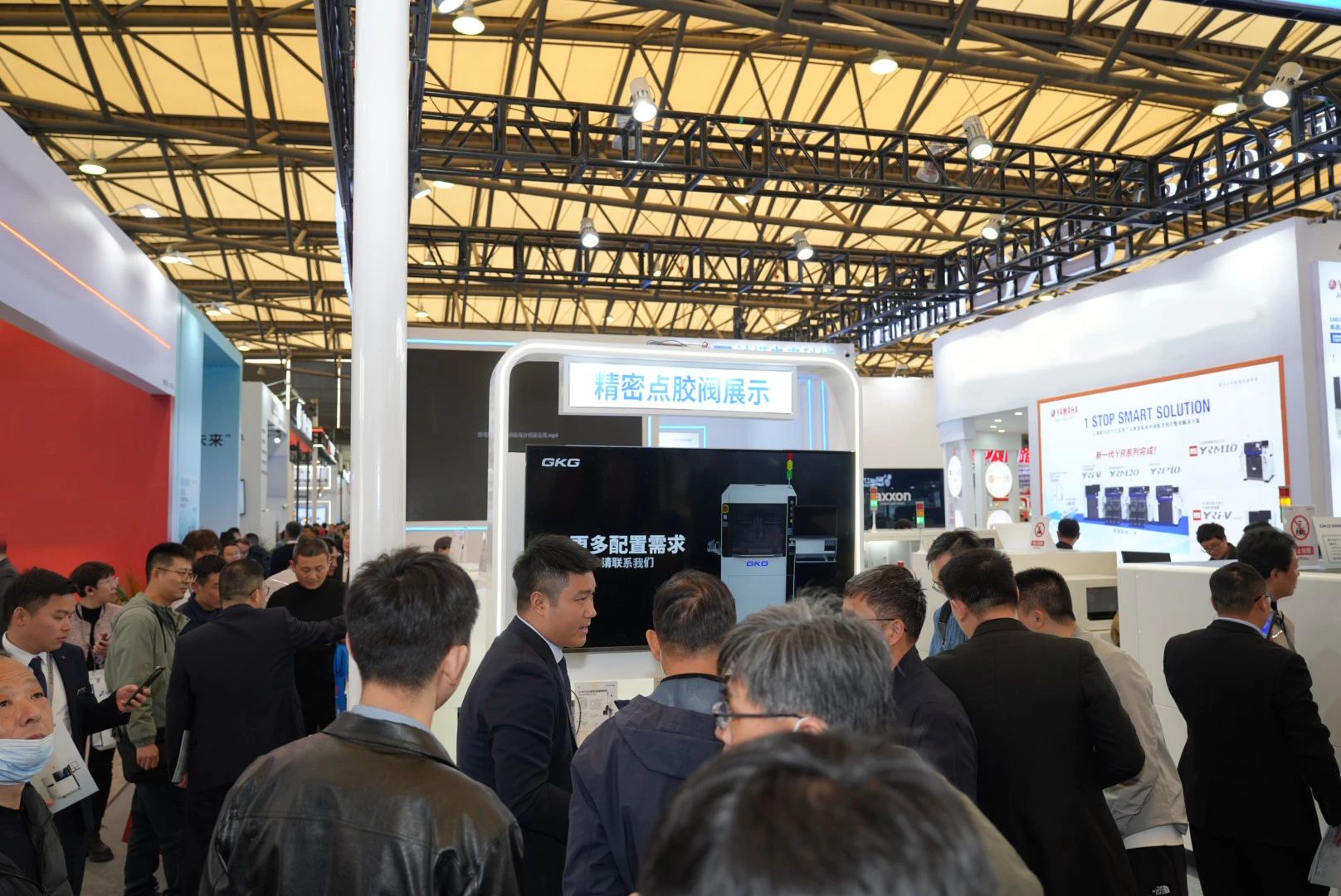

Dispensing processes are recognized as crucial technology in the electronics manufacturing industry, particularly in Surface Mount Technology (SMT). With the trend toward thinner, smaller, and higher-performance electronic products, the demands on dispensing processes are also increasing. GKG has independently developed a fully automatic high-speed dispensing machine, the D3S, equipped with precision dispensing valves. This ensures high stability, thereby guaranteeing the high reliability and quality of electronic products to a greater extent.

———— EXHIBITION RECAP ————

As technology continues to progress, solutions like Ares, G-Tera, and D3S will play a crucial role in driving forward the electronics industry, enabling manufacturers to meet consumer demands effectively while maintaining exceptional standards of quality.