|

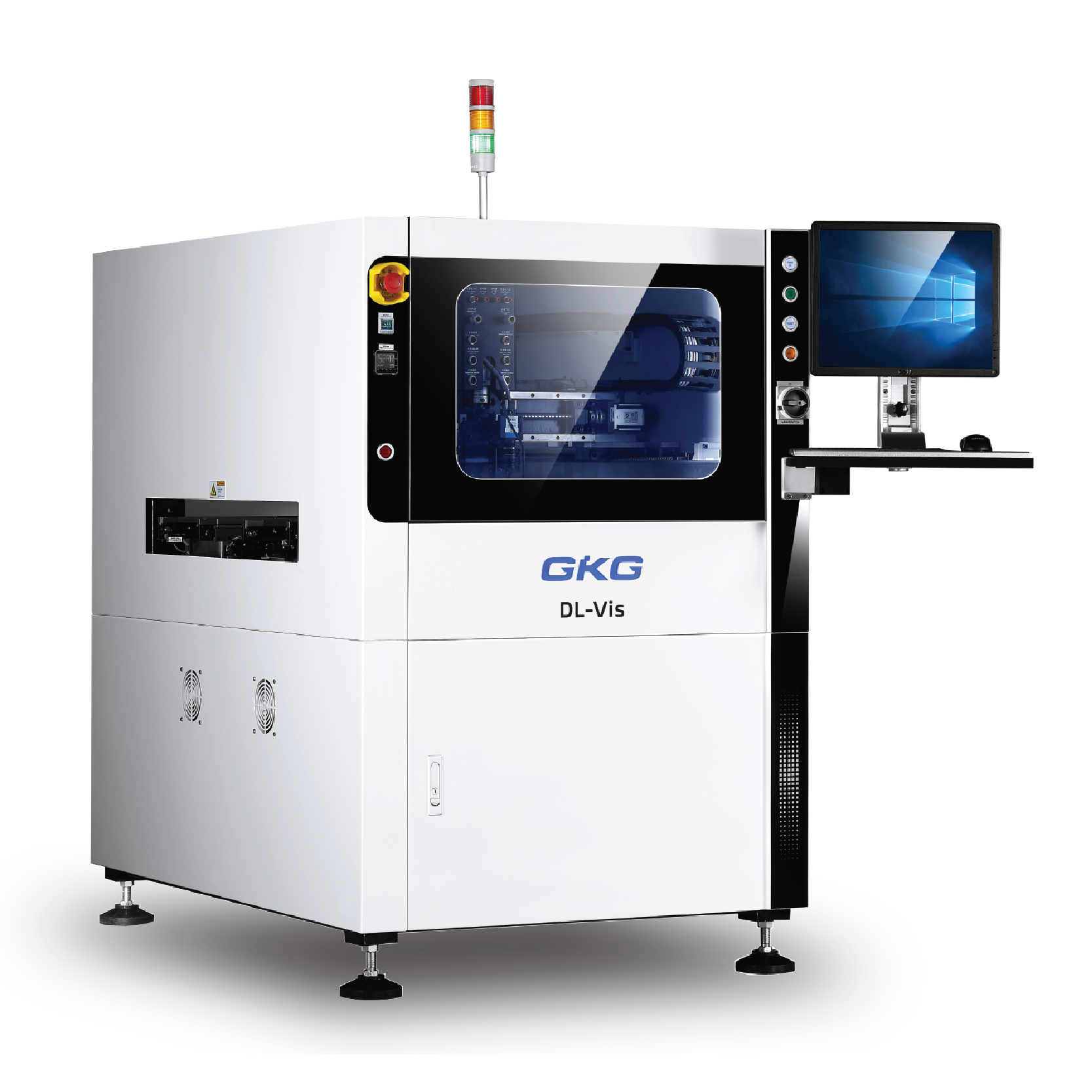

D-Vis & DL-Vis | Multi-function Dispenser

|

D-Vis & DL-Vis | MULTI-FUNCTION Dispenser

D Series Multi-function High Speed Dispenser

Equipped with fine volume control and positional accuracy which allows it to dispense discrete dots. D Series Machine can dispense into tight locations or close to a component in very thin lines without going out of bounds. Through non-contact dispensing, problems that are brought about by conventional dispensers are completely eliminated

DIVERSE APPLICATIONS

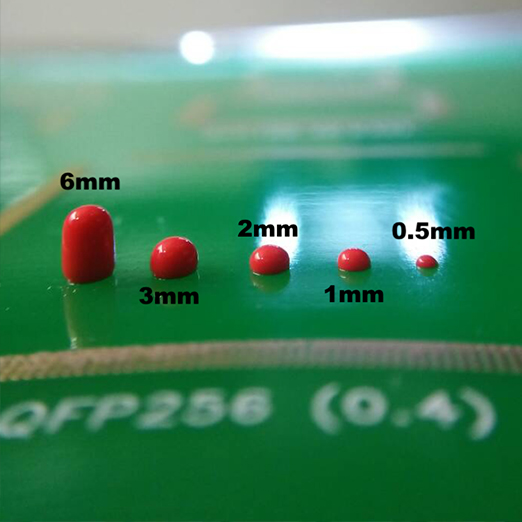

Stackable dotting process can create high profile dotting to ensure components will be glued strongly to the PCB. No tailing effect unlike other conventional smt dispenser.

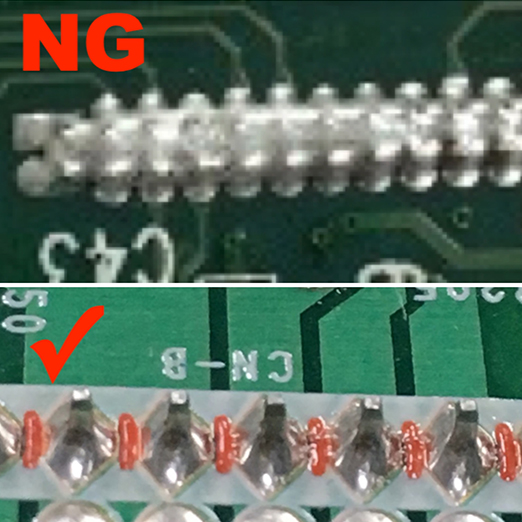

By jetting lines of glue between a series of PTH leads with narrow lead pitch such as connectors and sockets, solder bridging can be eliminated during wave soldering process.

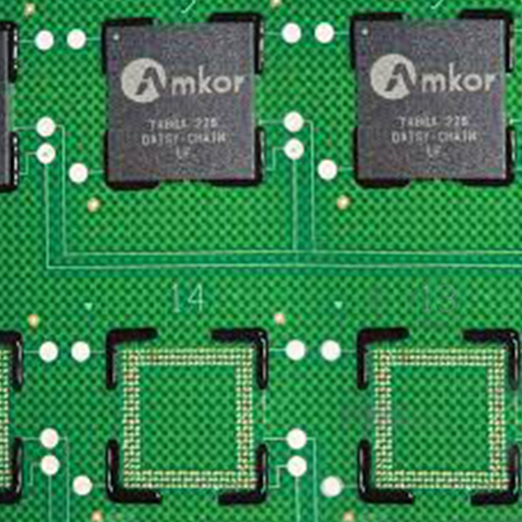

Corner bonding application can be done using our D-Sniper smt dispenser in a single SMT reflow process without any additional investment. SMA is dispensed on the PCB at the corners of BGA prior to placing the BGA. This application is not achievable by traditional contact dispensing as it is unable to create shapes and patterns thats adapted in Corner bonding. Through this application, there will be additional shock and bending resistance provided to the assembly when the PCB undergoes reflow.

(Photo Credits: Henkel AG & Co. KGaA)

Developed to protect components from dust, vibration, moisture, & other environmental condition, offering the longest possible operational lifespan for electronic devices. Without additional investment of conventional spray coating machine, D-Sniper can be converted into a jet coating machine

With an adequate amount dispensed (the smallest mark being 0.3mm), it ensures components remain robust & safely secured. The Precision Material Weight Calibration System (Option) would ensure a consistent underfill material volume being applied to every component.

D series machine capable to dispense (dot) red glue for mix technology PCB bottom side assembly to enhance mechanical bond strength. With CPK >1.33 accuracy, the dispense speed could perform up to 1000mm / second.

OPTIONS

With the self-integrated turning unit, it’s furnished with the ability of turning the nozzle to support angular position dispensing.

Dual Valve is capable of simultaneous dispensing with Active Correction Technology (ACT). ACT allows second valve adjust on Y axis for better dispensing performance. Also, it can provide independent dispensing with different material. It greatly aids in automated & high-mix production environment.

With dual lane, it will reduce the process time significantly, enhancing the throughput performance. It greatly aids in automated & high-mix production environment.

| STANDARD FEATURES |

| Single-stage conveyor with one or two PCB stop position |

| Material volume monitoring & low volume alarm |

| Laser height sensor |

| XYZ origin calibration function |

| Valve temperature regulators |

| Air stabilizer |

| Auto nozzle vacuum cleaning function |

| Small ultrasonic cleaning tank (External) |

| Programming by online teaching / CAD file importation |

| OPTIONS |

| Dual lane conveyor (Max. PCB size: L350 x W230 mm) |

| Dual-valve structure for simultaneous / alternative dispensing |

| Valve rotate and tilt function |

| Precision material weight calibration system |

| Auto nozzle wiping device |

| Camera 2D code scanner (Code size: L5 x W5~ L18 x W14 mm) |

| Internal/ External 2D code scanner (Code size: L5 x W5 ~ L25 x W15 mm) |

| Handheld barcode scanner |

| IC body recognition function |

D-Vis

| SPECIFICATIONS | |

| Dimension (W x D x H) | 770 mm x 1,400 mm x 1,480 mm |

| Machine Weight | Approx. 950 kg |

| Dispense Area (min.) | 50 mm x 50 mm |

| Dispense Area (max.) | 350 mm x 520mm |

| Positioning Accuracy | ± 30 micron @ 4 sigma (CPK>1.33) |

| Repeat Position Accuracy | ± 15 micron @ 4 sigma (CPK>1.33) |

| Air Supply | 4~6 Kgf/cm˜ |

| Power Supply | AC:220±10%, 50/60HZ, 2.5KW |

| Control Method | Industrial PC control with Windows 10 OS + Motion Control Card |

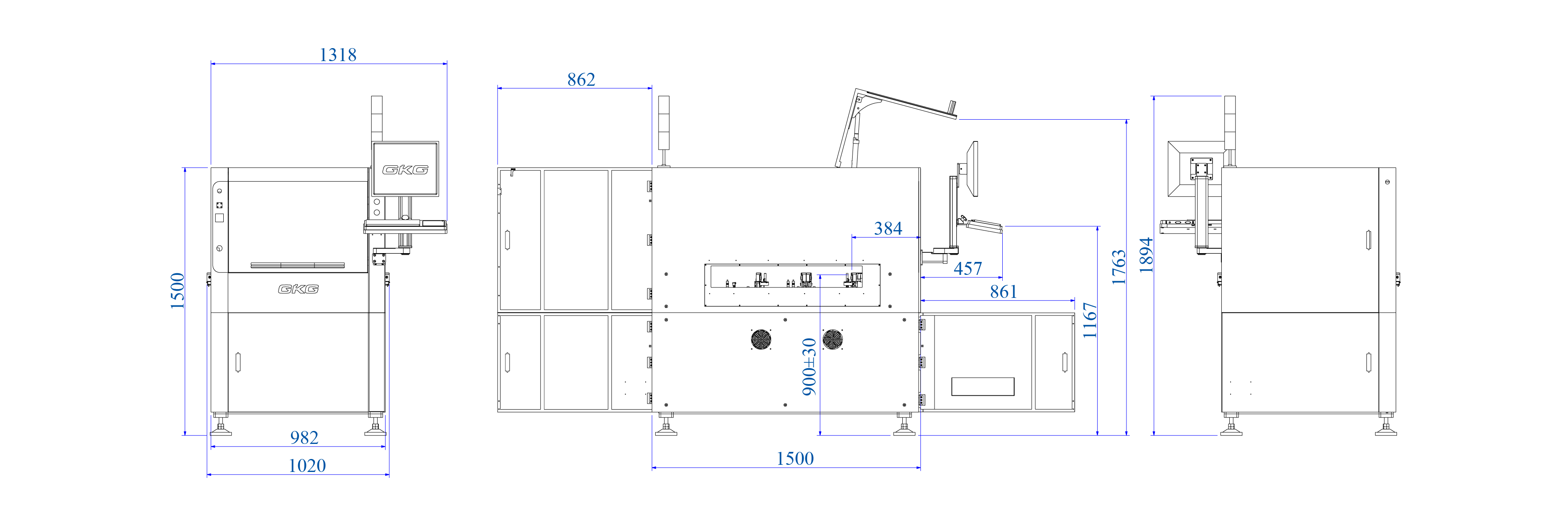

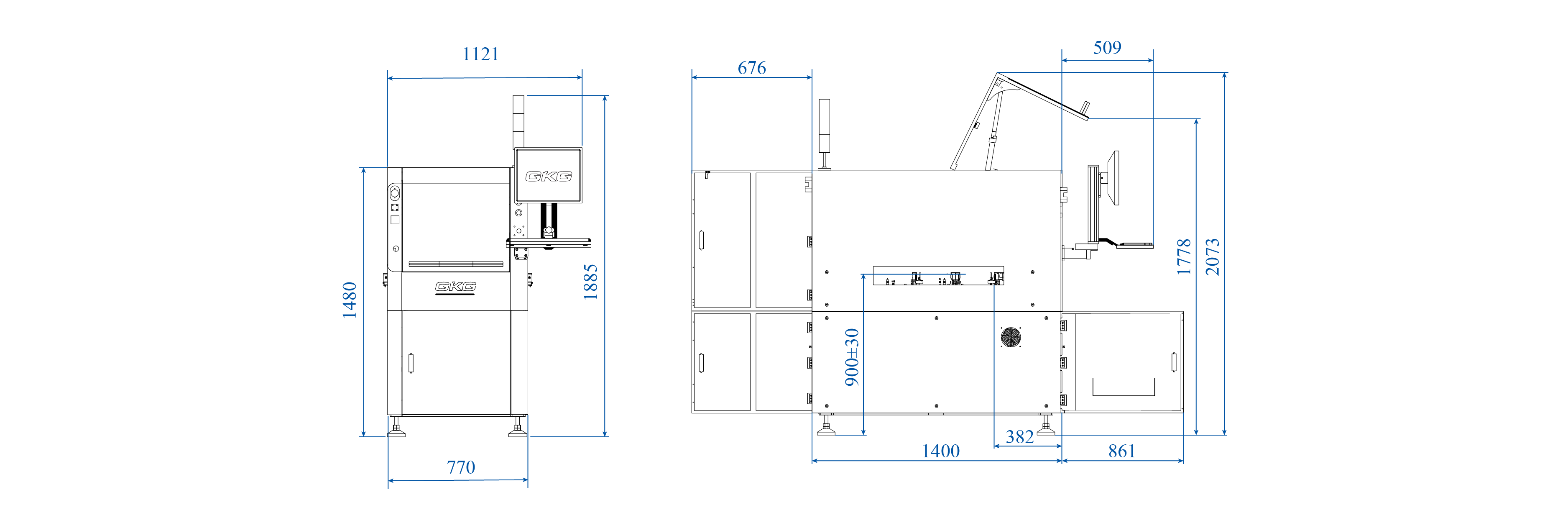

PRODUCT DIMENSION

DL-Vis

| SPECIFICATIONS | |

| Dimension (W x D x H) | 982 mm x 1,500 mm x 1,500 mm |

| Machine Weight | Approx. 950 kg |

| Dispense Area (min.) | 50 mm x 50 mm |

| Dispense Area (max.) | 510 mm x 650mm |

| Positioning Accuracy | ± 30 micron @ 4 sigma (CPK>1.33) |

| Repeat Position Accuracy | ± 15 micron @ 4 sigma (CPK>1.33) |

| Air Supply | 4~6 Kgf/cm˜ |

| Power Supply | AC:220±10%, 50/60HZ, 2.5KW |

| Control Method | Industrial PC control with Windows 10 OS + Motion Control Card |

PRODUCT DIMENSION