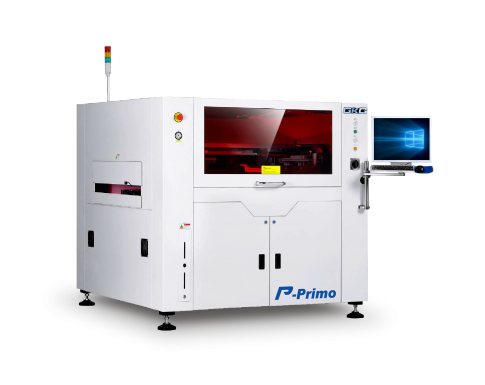

P-Primo

Brand :

,

The Large Platform Stencil Printer

Designed to meet customers’ ultra-large printing requirements, the P-Primo is the ideal solution for XL-sized PCBs, supporting board dimensions up to 850mm x 610mm. Equipped with 2D paste inspection, it effectively detects defects such as insufficient solder paste, bridging, and other printing defects.

To maintain high-quality printing, GKG’s printers undergo rigorous testing to ensure consistent performance and reliability.

| Performance | |

| Machine Alignment Capability | 2Cmk @ ±12.5 microns 4 Sigma |

| Process Alignment Capability | 2Cpk @ ±25 microns 4 Sigma |

| Core Cycle Time (excluding printing & cleaning time) |

< 12 secs |

| Product Changeover Time | < 5 mins |

| New Product Set-up Time | < 8 mins |

| Board Handling | |

| Max. Size (L x W) | 850 mm x 610 mm |

| Min. Size (L x W) | 100 mm x 65 mm |

| Thickness | 0.4~8 mm |

| PCB Thickness Adjustment | Automatic |

| PCB Max. Weight | 10 kg |

| PCB Edge Clearance | 3.5 mm |

| PCB Bottom Clearance | 23 mm |

| PCB Warpage | Max. 1% diagonally |

| Clamping Method | Retractable top clamp, motor controlled side clamp |

| Support Method | Magnetic support pins, bars, blocks, vacuum suction |

| Conveyor Direction | L to R, R to L, R to R, L to L (software control) |

| Conveyor Height | 900 ± 40 mm |

| Conveyor Speed | Max. 1,500 mm/s |

| Conveyor Width Adjustment | Automatic |

| OPERATOR INTERFACE | |

| Hardware | LCD Monitor, Mouse & Keyboard |

| Operating System (OS) | Windows 10 |

| Control Method | Industrial PC controlled |

| I/O Interface | SMEMA Standard |

| OPTICAL SYSTEM | |

| Field-of-View (FOV) | 10 mm x 8 mm |

| Fiducial Types | Circle, triangle, square, diamond, cross |

| Fiducial size | 0.5~4.0 mm |

| Vision Methodology | CCD camera look up & down |

| 2D inspection | Max. 500 windows to inspect missing, insufficient, bridging (std.) |

| PRINTING PARAMETERS | |

| Stencil Frame Size (L X W) | Adjustable, 650 mm x 650 mm to 1,100 mm x 950 mm |

| Print Gap (snap-off) | 0~20 mm |

| Printing Table Adjustment Range | X: ±10 mm, Y: ±10 mm/ : ± 2° |

| Print Speed | 5~150 mm/s |

| Squeegee Pressure | 0.5~30kg (program control) |

| Squeegee Type | Std.: Metal, Option: Rubber |

| Squeegee Angle | Std. 60°, Option 45°, 50°, 55° |

| Cleaning System | Auto wet, dry, vacuum (Software select) |

| FACILITIES REQUIREMENT | |

| Power Supply | AC220V ± 10% 50/60Hz |

| Power Consumption | 3kW |

| Air Supply | 4 ~ 6Kgf/cm² |

| Dimension (excluding signal tower) | 1,590 mm (L) x 1,608mm (W) x 1,530 mm (H) |

| Machine Weight | 1,500 kg |

| OPTIONS |

| Stencil Apertures Inspection System |

| SPI Closed-Loop |

| Temperature, Humidity Monitoring & Display |

| Camera Barcode/QR Code Scanner for PCB Traceability |

| External Barcode/QR Code Scanner for PCB Traceability |

| Handheld Barcode Scanner for stencil, solder paste, squeegee traceability |